Multi-modal flotation provides two methods of separating artifacts from a soil matrix. It provides a rudimentary form of coarse-fraction classification and a capacity for large matrix samples. It can be used in the laboratory or in the field and is especially useful in arid locations or areas where discharge of silty water is restricted. When used in the field, it conserves water and reduces environmental pollution.

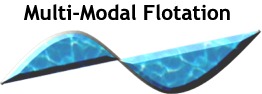

The system consists of a water reservoir, flotation tank and a water pump. The pump is used to move the 100-gallon water supply in a closed loop from the water reservoir into the floatation tank through discharge nozzles, up through the coarse-fraction screen, over a weir to the fine-fraction screen and back into the water reservoir.

In remote locations, the water pump may be operated by electricity supplied by a portable generator.

Mode 1 is shown in Figure 1. Soil matrix is dumped into the flotation tank where the sediment drops to the sediment collector. The coarse fraction remains on the coarse-fraction screen, and the floatables are deposited on the fine-fraction screen. This system will process samples up to 20 litres in volume. The composition of the matrix in each sample will determine the processing rate.

This mode incorporates minute air bubbles into the water entering the flotation tank by opening the air-inlet valve. The bubbles attach to the artifacts as they drop away from the sediment in the flotation tank. When attached to small artifacts with a specific gravity greater than 1, these bubbles can cause the artifacts to rise and be recovered with the fine fraction. This feature increases the efficiency of flotation.

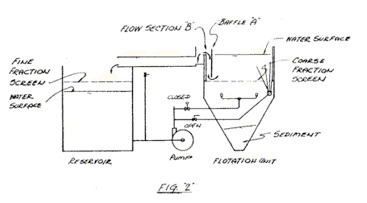

Mode 2, shown in Figure 2, is a coarse-fraction classification mode and is used only after mode 1 has removed the floatables and the sediment. As shown, the entire water stream is forced to flow under baffle A and up the side of the flotation tank at flow-section B. Because the volume of the water passage at B is restricted, the upward velocity of the water stream at B and under baffle A is greatly increased compared to mode 1.

To remove from the coarse fraction small artifacts that have a specific gravity greater than 1 (near-floatables), the coarse fraction is manually moved near the bottom of baffle A. When the artifacts move into the high-velocity water stream flowing under baffle A, they are swept up flow-section B and onto the fine-fraction screen. Artifacts removed in this mode are not damaged in the high-velocity water stream; the shape of flow-section B does not create turbulent flow conditions, only sufficient velocity to sweep the near-floatables away from the rest of the coarse fraction.

Mode 2 removes near-floatables from the coarse fraction on the basis of artifact mass, not specific gravity. At low-water velocity, near-floatables of small mass are swept from the coarse fraction; as the velocity is increased, near-floatables of greater mass are removed. Since water velocity can be regulated with the flow-control valve, mode 2 provides a limited method of artifact classification.

This technique of removing near-floatables is much more efficient than the current method of picking through the coarse fraction with tweezers and a magnifying glass.

Near-floatables include water-saturated wood or charcoal, as well as small fragment of shell, bone, fish scales, nutshell, ceramics and chert.

The fine and coarse-fraction screen opening sizes are selected to suit the requirements of the user. The opening diameter of the fine-fraction screen determines the minimum size of the fine fraction and the size of those objects that may continuously circulate in the system from one sample to the next. The opening diameter of the coarse-fraction screen defines the sediment particle size. The system uses nylon and polyester screen fabric, which is available in a wide range of opening sizes.

In all modes of operation, the rate at which water can be circulated in the system can be varied from 1 to 80 gallons per minute.

The sediment is removed from the sediment collector by a manual pump. This water-sediment mixture is pumped into a suitable container, such as a five-gallon bucket, and set aside to settle. After settling, the clear water supernatant is returned to the system. The sediment can be discarded or used as excavation fill.

Clay dispersing agents or other flotation-enhancing agents may be put into the water reservoir and recycled in the system for as long as necessary.